The Hyundai Motor Group is paving the way for the future of electric vehicles by establishing a local production system for battery cells and electric cars in Indonesia.

Hyundai Motor Group has completed the battery cell factory “HLI Green Power,” a joint venture with LG Energy Solution. The Hyundai Indonesia Plant will begin mass production of the “All-New Kona Electric” equipped with battery cells produced at HLI Green Power.

As a result, Hyundai Motor Group has established the first local production system in Indonesia that integrates everything from electric vehicle battery cells to complete vehicles, thus positioning itself for strategic advantage in the ASEAN electric vehicle market beyond Indonesia.

Indonesia, the world’s fourth most populous country and a key member of the ASEAN, holds explosive growth potential. It also boasts the world’s largest reserves and production of nickel, a key mineral for electric car batteries, solidifying its status in the raw materials supply chain.

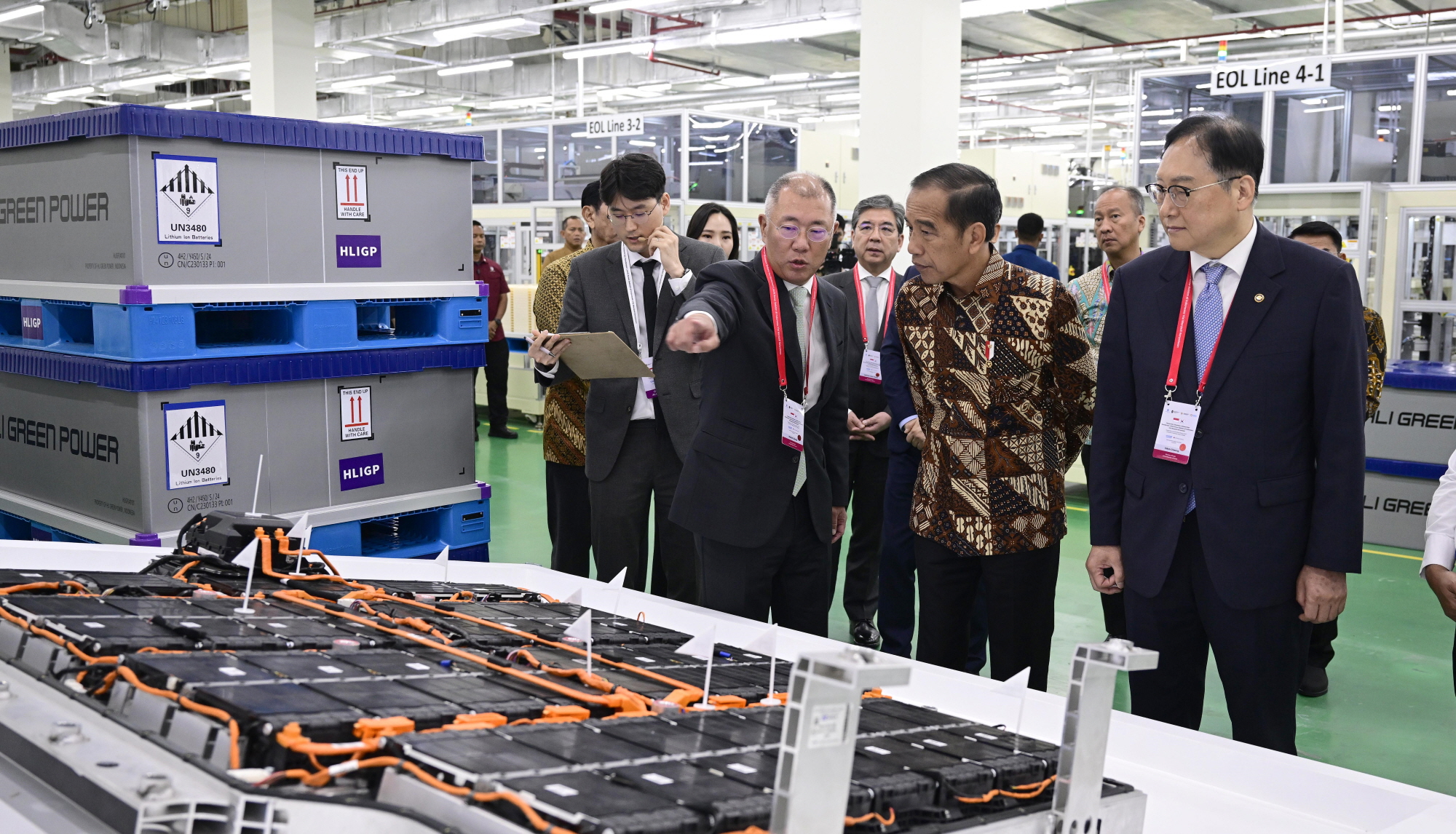

On July 3, local time, Hyundai Motor Group held a ceremony with the Indonesian government at HLI Green Power located in the Karawang New Industrial City to commemorate the completion of the facility and the mass production of the Kona Electric. About 300 attendees from both Korea and Indonesia participated in the ceremony.

The ceremony was attended by Indonesia’s President Joko Widodo, Minister of Coordinating Maritime Affairs and Investment Luhut Binsar Pandjaitan, Minister of Investment Bahlil Lahadalia, Minister of Industry Agus Gumiwang Kartasasmita, Minister of State-Owned Enterprises Erick Thohir, and West Java Governor Ridwan Kamil, among others. Key figures from the Korean government, including Trade Negotiation Headquarters Director Jeong In-kyu and Ambassador to Indonesia Lee Sang-deok, were also present.

Chairman Euisun Chung of Hyundai Motor Group, President Jae-hoon Chung of Hyundai Motor, and President Dong-myung Kim of LG Energy Solution, along with local employees from HLI Green Power and the Hyundai Indonesia Plant, were also present.

President Joko Widodo remarked in his speech that “this will be reflected going forward.”

Chairman Chung highlighted in his address that, “The completion of the battery cell factory in Indonesia and the mass production of the Kona Electric represents a fruitful cooperation between Hyundai Motor Group and Indonesia, symbolizing our strong partnership and showcasing our joint role in shaping the future electric vehicle ecosystem globally, not just in Asia.”

He added, “Vehicles produced and sold in Indonesia are setting new standards for potential customers in the Southeast Asia region, and revitalizing the electric car industry in Indonesia will provide new economic opportunities for the entire region.”

Moreover, Chairman Chung emphasized, “Hyundai Motor Group will strengthen its collaboration with Indonesia and explore new areas, ranging from resource-recirculating hydrogen solutions to future aerial mobility,” stressing that “we will forge the future together in the spirit of ‘Membuka jalan baru’ (Opening a new way).”

Director Jeong In-kyu noted in his speech, “I sincerely congratulate Hyundai Motor on becoming the first to mass produce electric vehicles equipped with Indonesian-made batteries. This facility will lead the advancement of Indonesia’s electric vehicle industry.”

During the event, President Joko Widodo personally assembled battery cells produced at HLI Green Power into battery modules and packs, further emphasizing the significance by signing the first All-New Kona Electric vehicle produced in Indonesia. He had previously signed the Kona Electric at the investment contract ceremony for the Indonesian plant in Ulsan in 2019.

■ Hyundai Motor Group Establishes a Core Foundation for the ASEAN Electric Vehicle Ecosystem Beyond Indonesia, Expanding Back and Forth

The establishment of the battery cell electric vehicle production system by Hyundai Motor Group carries significant implications, not only for Indonesia but also for creating a core foundation for the ASEAN electric vehicle ecosystem.

With large-scale investments, Hyundai Motor Group is implementing a global electric vehicle ecosystem centered around South Korea. In Indonesia, they are developing a local electric vehicle ecosystem that encompasses “raw material procurement – battery and vehicle production – expansion of charging systems – battery recycling”, thereby securing leadership in the ASEAN electric vehicle market, including Indonesia.

Among these, the most crucial aspect is the ability to produce battery cells, battery packs, and complete vehicles locally, allowing for greater flexibility in expanding the ecosystem both backward and forward.

First, HLI Green Power, co-established by Hyundai Motor Group and LG Energy Solution in the Karawang New Industrial City, broke ground in September 2021 and began producing battery cells in the second quarter of this year after undergoing trial production last year.

Covering a total area of 320,000 square meters, it is equipped with electrode processes, assembly processes, and activation processes, and has an annual production capacity of 10 gigawatt-hours (GWh) of battery cells, sufficient for over 150,000 electric car batteries. Battery cells, the most fundamental component of a car battery, are assembled in the order of modules and packs before final installation in vehicles.

The battery cells produced at HLI Green Power are high-performance NCMA lithium-ion battery cells augmented with aluminum (Al), increasing output while lowering chemical instability, containing high nickel (N), cobalt (C), and manganese (M). They will be used in electric vehicles produced at the Hyundai Indonesia plant as well as in various Hyundai and Kia models.

Specifically, the battery cells produced at HLI Green Power will be installed in the All-New Kona Electric, set to launch in Indonesia on the 17th.

The Kona Electric is the second electric vehicle model produced at the Hyundai Indonesia Plant (completed in March 2022), following the Ioniq 5, and is expected to play a significant role in the growth of the Indonesian electric vehicle market. Hyundai plans to launch the Kona Electric, equipped with futuristic design, best-in-class driving range, connectivity technologies, and advanced safety specifications, while running diverse marketing campaigns tailored for electric vehicles. This strategy aims to elevate the Kona Electric as a representative electric vehicle of Indonesia.

Additionally, Hyundai Motor Group is working with various companies to secure a stable supply chain for key raw materials like nickel for electric vehicle batteries in Indonesia and is accelerating the establishment of public charging infrastructure. They are also researching ways to utilize used batteries to ensure a resource recirculation within the electric vehicle lifecycle.

The ecosystem-building model of Hyundai Motor Group in Indonesia is expected to create positive synergies not only for electric vehicle sales in Indonesia but also for ASEAN and even for global sales.

■ Expanding EV Lineup, Enhancing Specialized Customer Experience, and Strengthening Charging Services to Leap Forward as a Top-Tier Brand in Indonesia

Indonesia, aiming for carbon neutrality by 2060, has aggressively implemented policies to nurture its electric vehicle industry, announcing a goal of producing 600,000 electric vehicles by 2030.

In Indonesia, buyers of electric vehicles are exempt from the two-part traffic restrictions implemented to avoid congestion, and they can benefit from sales tax exemptions or reductions that reach between 12% and 15% in major cities like Jakarta.

Moreover, electric vehicles that meet localization requirements using local components and labor enjoy an exemption from the luxury tax (15%) and a temporary reduction of 10% in value-added tax (from 11% to 1%).

Furthermore, the Indonesian government plans to convert over 130,000 vehicles used by the government to electric by the year 2030, with an annual target of over 10,000 vehicles from 2021 onwards.

While electric vehicle demand in Indonesia stood at only 18,000 units in 2023, accounting for 2% of the total industry demand, projections estimate it will record double-digit market share by 2030. As Chinese electric vehicle manufacturers intensify their entries into the Indonesian market, competition for electric vehicles is expected to become more fierce.

Hyundai aims to establish a positive image as the only brand with a fully local production system in Indonesia, leading the country’s electric vehicle market by providing a variety of electric vehicle lineups and specialized customer experiences.

First, the electric vehicle lineup will be expanded. Hyundai, having secured a premium electric vehicle branding with the Ioniq 5 and Ioniq 6, plans to successfully launch the All-New Kona Electric this year to lay the foundation for mainstream electric vehicles and continue introducing models tailored to the Indonesian market.

Moreover, the company will strengthen its specialized customer experience for electric vehicles. By expanding EV specialist mechanics and dedicated service facilities, they aim to enhance customer satisfaction regarding electric vehicle after-sales service. They will also ensure that dealer showrooms are equipped with charging facilities, thus providing unique experiences solely for Hyundai customers. Programs such as an EV-exclusive warranty program and free inspections will be implemented.

Concerning charging services, Hyundai will roll out services that cover home, public spaces, and mobile options. They will install home chargers for free upon the purchase of an electric vehicle and offer a year’s worth of charging benefits. Additionally, they are collaborating with charging service providers in Indonesia to allow Hyundai customers to utilize charging services through their own apps at various charging stations.

Hyundai aims to expand its electric vehicle charging stations in collaboration with Indonesian retail companies and hotel chains, targeting key areas frequented by electric vehicle customers to provide convenient charging experiences.

Written by Lee Sang-jin daedusj@autodiary.kr