BorgWarner has signed a supply agreement for exhaust gas recirculation (EGR) coolers with a well-known North American commercial vehicle customer, strengthening its thermal management business. The exhaust gas reduction EGR solution boasts ruggedness that reduces thermal fatigue while optimizing internal design to minimize coolant flow in the engine. Production is slated to begin in the fourth quarter of 2027, with applications across various commercial vehicle platforms.

Volker Bang, Vice President and President of Turbo and Thermal Solutions at BorgWarner, stated, “The interest in our EGR product portfolio, which includes coolers, valves, and modules that meet stringent fuel economy and emissions standards, continues to grow. Recent program awards are a natural result of the close collaborative relationship our team has built with the customer, proving BorgWarner’s industry-leading position and our outstanding, rich track record in similar applications.”

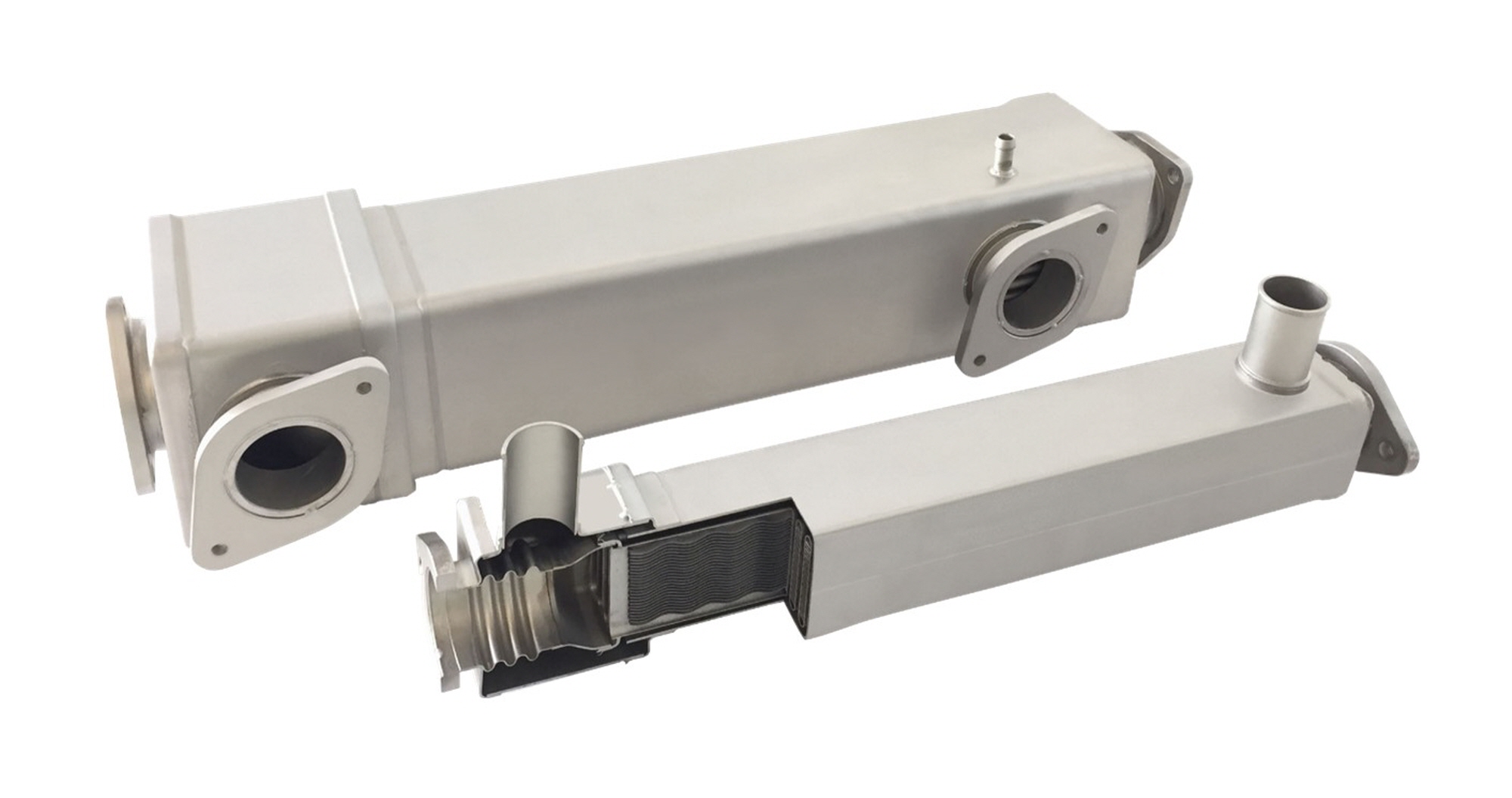

BorgWarner offers two durable EGR cooler products to support cooling for various engine sizes. One is designed using the patented Compact Floating Core (CFC) technology, while the other employs monoblock design technology to meet more compact package requirements. BorgWarner developed CFC to alleviate stress on commercial vehicle engines caused by high temperatures, enhancing lifespan and reliability. Additionally, the CFC architecture, combining high-efficiency hybrid tube heat transfer technology with a floating core, achieves strong durability with compact packaging to help reduce thermal fatigue. The monoblock architecture is a cost-optimized solution used in many passenger and mid-sized vehicle applications to reach target reliability values.

BorgWarner’s modular EGR cooler product line includes four flexible designs that cover engine sizes ranging from 2.0 to 16.0 liters of displacement. These coolers support the standardization of most core components, excluding the housing and mounting, making it easy to apply the technology from one application to another. Since introducing this technology to the industry, BorgWarner has supplied over one million EGR coolers and developed advanced modeling tools to optimize designs, prevent boiling phenomena, and enhance performance.

Lee Sang-jin daedusj@autodiary.kr