BMW Group has commenced operations of its battery cell coating line at the Leipzig plant in Germany as the first step towards high-voltage battery production.

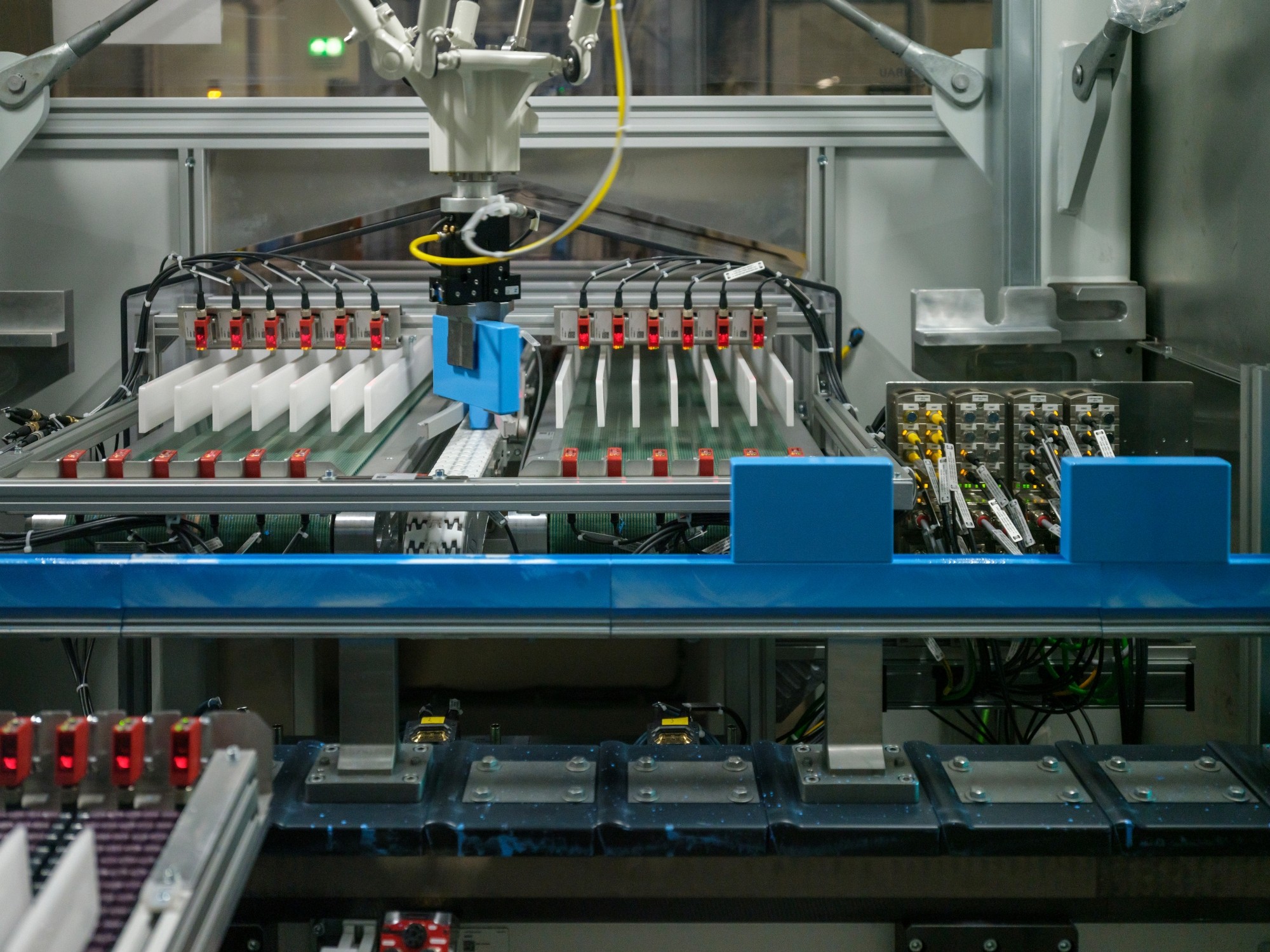

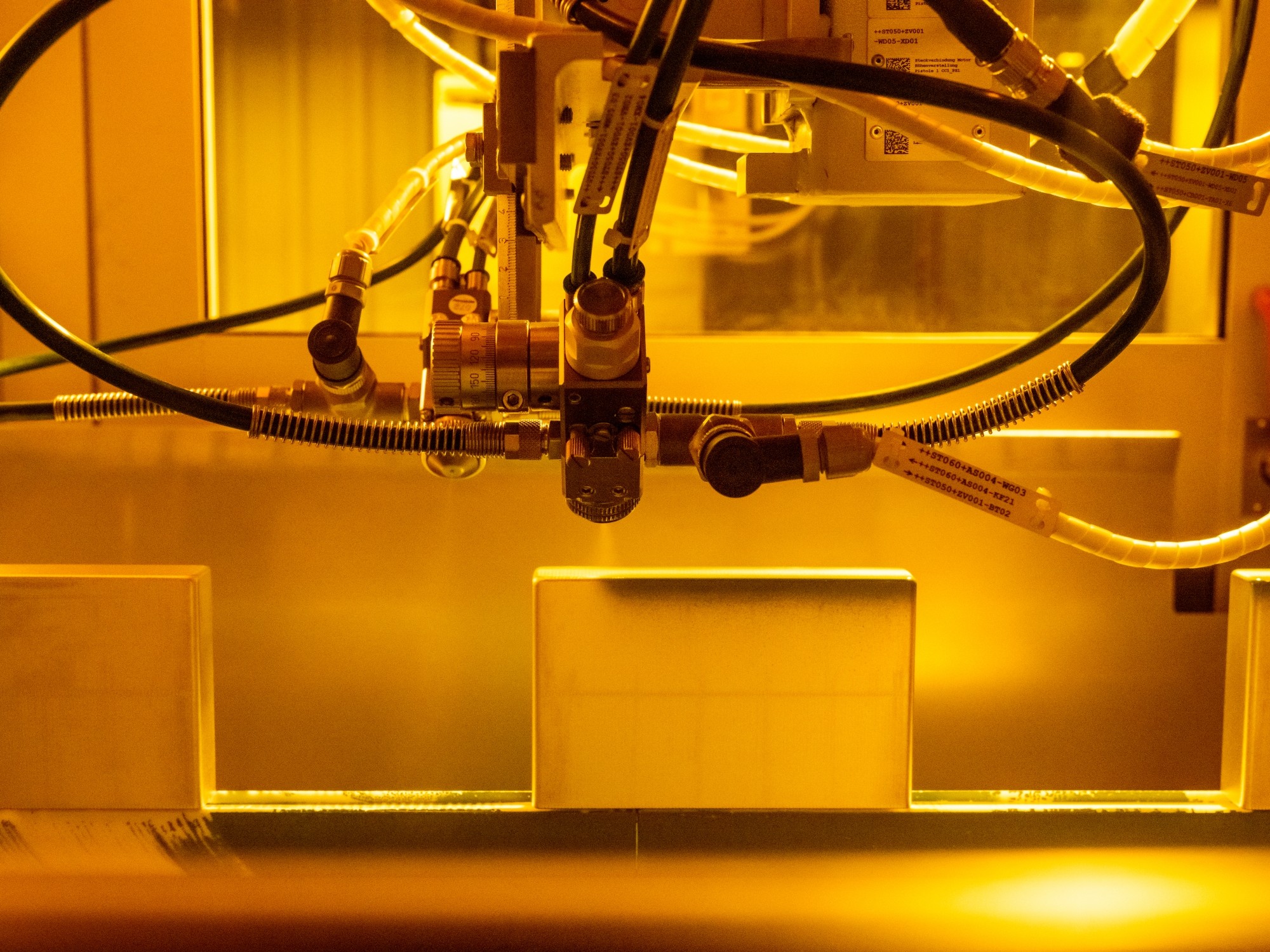

The high-voltage battery production is divided into three stages: cell coating, module production, and battery assembly. The cell coating process is aimed at insulating battery cells to safely assemble them into battery modules, and the complete battery product production, including battery cell coating and module assembly, will be carried out through automations at the BMW Group Leipzig plant.

In order to achieve its goal of producing more than half of its total sales as all-electric vehicles by 2030, BMW Group is investing over 800 million euros at the BMW Leipzig plant and is actively working on the development and production of electric vehicle components.

To this end, it plans to increase its current two battery pack assembly lines to three by 2024, adding four cell coating lines and two high-voltage battery assembly lines. The four cell coating lines are expected to be added at a rate of one every two months, with full operation anticipated within this year.

Markus Fallböhmer, head of battery production at BMW Group, stated, “By 2024, the BMW Group Leipzig plant is expected to take charge of the entire series of processes for producing high-voltage batteries. This means the Leipzig plant will play a key role in the BMW Group’s transition to electric vehicles,”

Meanwhile, the new battery cell coating line at the BMW Leipzig plant occupies an area of 2,300 square meters and can coat more than 10 million battery cells per year, equating to a speed of about 2,300 cells per hour. The coated cells are fed into the battery module production line at the Leipzig plant to be integrated into pure electric models like the BMW i4 and BMW iX1. Future additional lines are also planned to produce battery modules for the BMW iX.

Lee Sang-jin daedusj@autodiary.kr