STMicroelectronics has launched a new high-power module designed to enhance the performance and driving range of electric vehicles. This new SiC (Silicon Carbide) power module from ST has been adopted into Hyundai Motor’s E-GMP electric vehicle platform, which is used across various vehicle models, including the Kia EV6.

Through five types of new SiC-MOSFET-based power modules, vehicle manufacturers can support the operating voltage commonly used in traction applications for electric vehicles, and flexibly choose from various rated power levels.

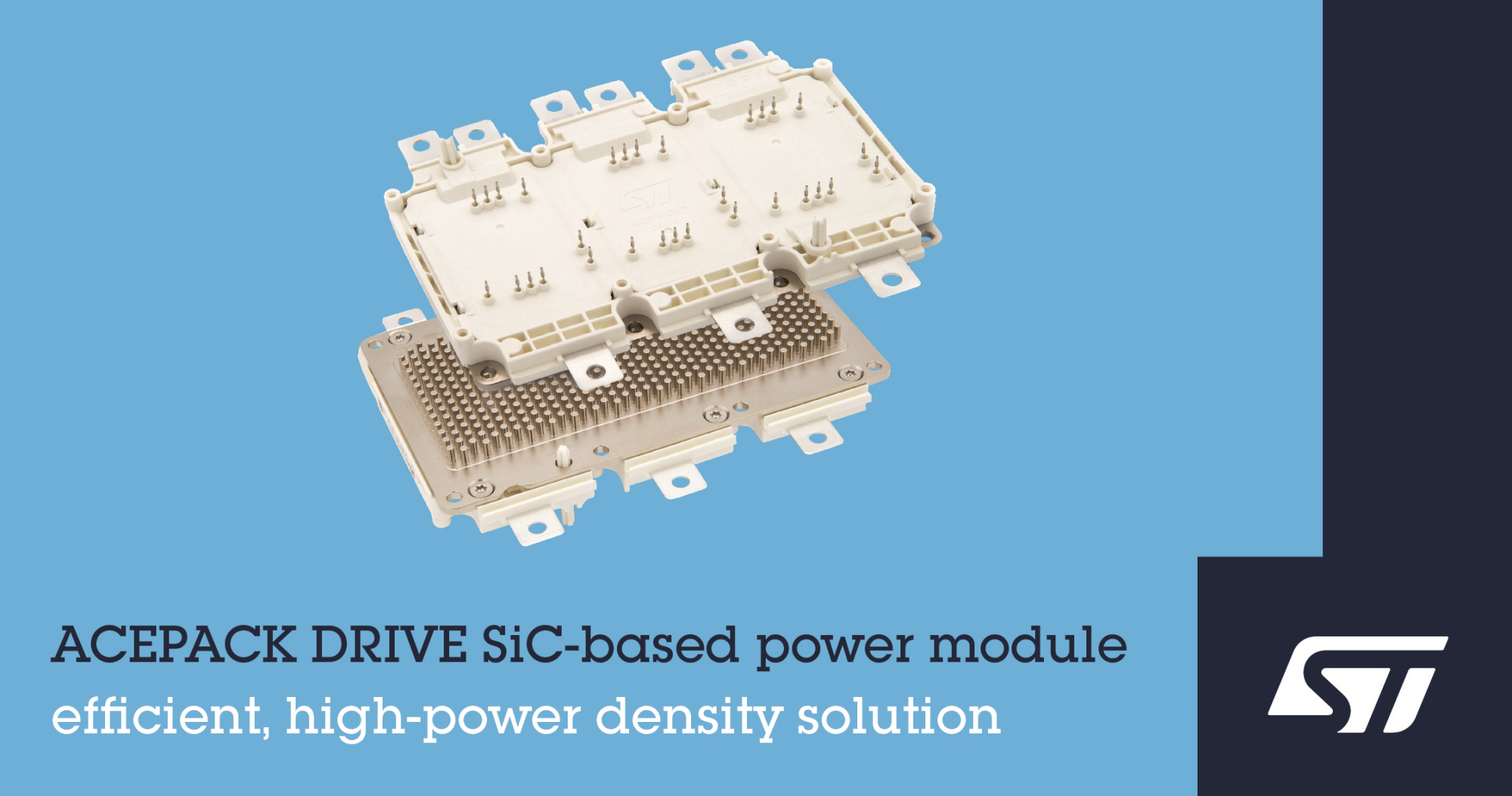

ST’s Acepack drive power module, housed in a package optimized for traction applications, offers high stability and robustness, thanks to sintering technology, making it easy for manufacturers to integrate into electric vehicle drives. The key power semiconductor embedded in this power module is ST’s third-generation STPOWER SiC MOSFET, which delivers excellent performance in synchronous rectification and provides industry-leading performance index (RDS(ON) x die area) with very low switching energy.

Marco Monti, President of ST’s Automotive and Discrete Group, stated, “ST’s Silicon Carbide solutions support major automotive OEMs in accelerating electrification processes in the development of next-generation electric vehicles,” adding that “ST’s third-generation SiC technology ensures the highest power density and energy efficiency, achieving superior vehicle performance, driving range, and charging time.”

Hyundai Motor Company, a leader in the electric vehicle market, has adopted ST’s third-generation Acepack drive SiC-MOSFET-based power module in its current-generation EV platform, E-GMP. Notably, this module is set to power the Kia EV6 model.

Shin Sang-cheol, team leader of the Hyundai Motor Group inverter design team, stated, “ST’s SiC-MOSFET-based power module is the optimal solution for traction inverters that support longer driving ranges,” and added, “We have made significant advancements towards realizing more sustainable electric vehicles through collaborations with ST, a leading semiconductor company innovating electrification through continuous technology investment.”

Leading in SiC technology, ST has already supplied STPOWER SiC devices to over 3 million passenger cars in mass production worldwide. Compared to traditional silicon power semiconductors, SiC devices can handle higher operating voltages in a smaller size, enabling faster charging and superior vehicle power. They enhance driving range with better energy efficiency and increased reliability.

SiC is being widely adopted in various electric vehicle systems, from DC-DC converters and traction inverters to onboard chargers capable of bidirectional operation that transmit power from the vehicle to the grid. ST, as an integrated device manufacturer, supports automakers’ electrification strategies through its SiC strategy that guarantees the quality and security of power supply systems. Recently, ST has established a fully integrated SiC substrate manufacturing facility in Catania, Italy, set to commence production in 2023, to rapidly respond to the rapidly expanding electric mobility market.

Lee Sang-jin daedusj@autodiary.kr