Amid growing concerns over the safe use of electric vehicle batteries, LG Energy Solution is embarking on a significant expansion of its ‘Battery Safety Diagnosis Software’ business, built on differentiated technological capabilities.

LG Energy Solution has harnessed its unique technological prowess accumulated over 20 years in the Battery Management System (BMS) design capabilities and empirical data for the ‘Battery Safety Diagnosis Software’ domain.

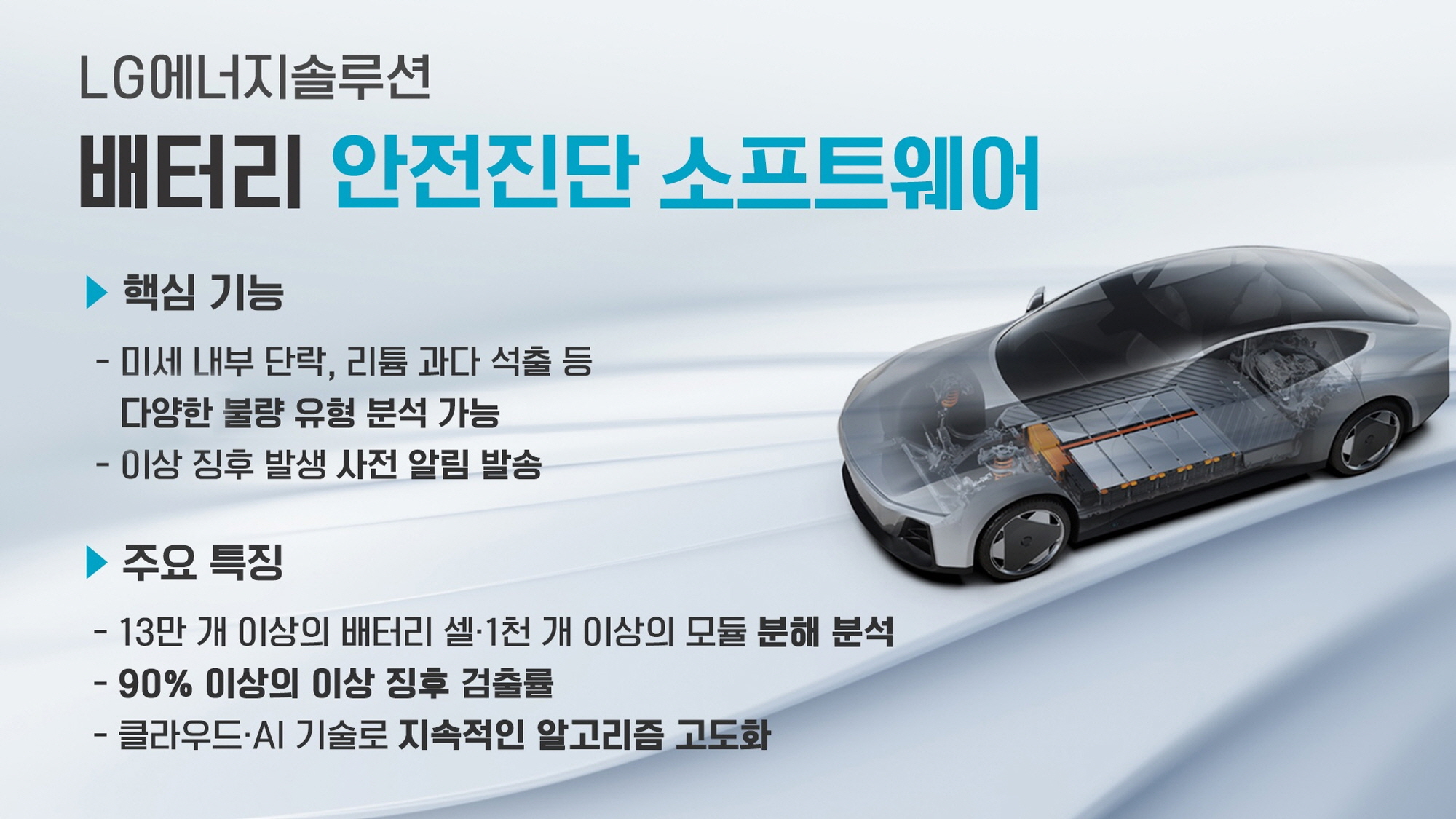

Holding over 8,000 patents in the BMS field where safety diagnosis software is applied, it has developed technology based on empirical data from disassembling and analyzing more than 130,000 battery cells and over 1,000 modules.

Interestingly, its software has already been applied to over 100,000 electric vehicles, achieving a detection rate of over 90% for safety diagnostics.

Based on this technology, LG Energy Solution’s ‘Safety Diagnosis Software’ can analyze various defect types, including: ▲ Voltage drop during charging ▲ Faulty battery tabs ▲ Minor internal short circuits ▲ Abnormal degradation ▲ Abnormal discharge ▲ Capacity deviation of specific cells ▲ Excess lithium precipitation.

Previously, most existing battery diagnosis software developed technologies based on hypothetical conditions, which raised concerns about accuracy when applied in real-world environments.

With increasing interest in the safe use of electric vehicle batteries, the importance of precise battery state management is growing. Automotive manufacturers are focusing on the capabilities of BMS to measure and analyze battery data to identify issues proactively.

LG Energy Solution’s safety diagnosis software is applied to automotive BMS, providing capabilities for early diagnosis of battery anomalies. It is already being used in vehicles from nine global automakers.

With a safety diagnosis detection rate exceeding 90%, it can identify warning signs that could lead to fires, allowing customers to use their electric vehicles with peace of mind over the long term. Moreover, it is noteworthy that it can also be applied to vehicles equipped with batteries from other manufacturers.

Building on its proven accuracy in safety diagnosis and accumulated technical capabilities, LG Energy Solution plans to start collaborating and selling its safety diagnosis software at the request of automotive manufacturers.

An official from LG Energy Solution said, “While interest in safety diagnosis technology among automakers is rising, developing or applying reliable software requires considerable time and resources. LG Energy Solution has already secured diagnostic detection power that surpasses competitors along with related patents and empirical data, which enables immediate application to automotive BMS. We are committed to actively collaborating with customers for the safe use of electric vehicle batteries.”

LG Energy Solution has also developed precise diagnosis and predictive technologies for battery degradation, in addition to safety diagnosis technology.

LG Energy Solution’s BMS software can predict future battery residual capacity and degradation state based on the vehicle’s driving patterns. This process incorporates a battery physical model reflecting various complex degradation mechanisms, including lithium precipitation and the degradation of anodes and cathodes, based on the company’s electrochemical expertise in batteries.

By leveraging AI computing technology to continuously enhance its algorithms, the software achieves more accurate battery state diagnosis. The company has reduced the error rate for battery degradation diagnosis to industry-leading levels of around 1% by continuously applying and supplementing various electric vehicle battery cell information into the algorithm.

Additionally, to analyze vast amounts of battery data in real-time, LG Energy Solution employs cloud technology. As of last year, it collected and analyzed battery data from 12,000 vehicles, accounting for approximately 2.2% of domestic electric cars.

With future mobility aiming for vehicles as new lifestyle platforms, LG Energy Solution is also developing BMS hardware and software optimized for the Software Defined Vehicle (SDV) platform. By utilizing the vehicle’s System-on-Chip (SoC) computing performance, it enhances computational power to implement more sophisticated battery algorithms. This also makes it possible to offer users new battery services by utilizing additional information directly acquired from the vehicle.

In March, LG Energy Solution partnered with Qualcomm to collaborate on developing advanced BMS diagnostic solutions based on SoC, and it signed an MOU with semiconductor company ADI to ensure a stable supply of high-performance battery management chips and collaborate on technology development.

Kim Dong-myung, CEO of LG Energy Solution, stated, “We will continue to provide unparalleled differentiated customer value not only in battery manufacturing but also in the BMS solution field, ensuring safe and healthy use.”

Lee Sang-jin daedusj@autodiary.kr