Polestar has announced its first Life Cycle Assessment (LCA) report for the Polestar 4. According to the report, producing a Polestar 4 generates 19.4 tons of greenhouse gases (CO2e), making it the lowest carbon footprint of any mass-produced vehicle developed by Polestar to date.

The Polestar 4 is produced at the Geely Holding SEA plant located in Hangzhou Bay. This facility combines environmentally friendly electricity from internationally certified renewable energy sources, particularly hydropower, with solar power generated from panels installed on the plant’s roof. The more low-carbon aluminum produced in such hydropower plants is utilized, the greater the reduction in climate change impacts. Notably, this assessment includes data on the ratio of recycled aluminum for the first time.

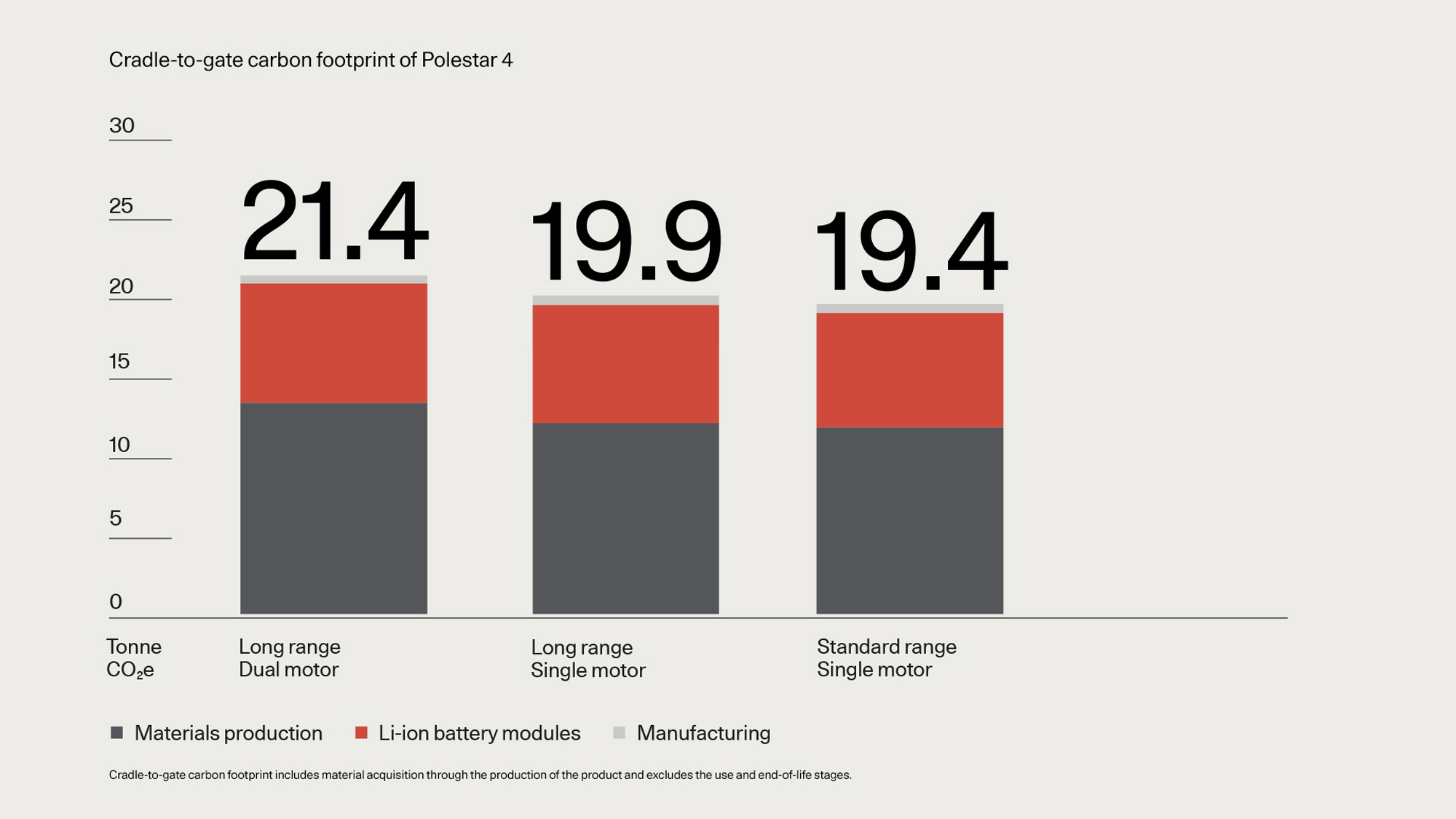

The Polestar 4’s standard range single motor emits 19.4 tons of greenhouse gases, while the long-range single motor and long-range dual motor versions emit 19.9 tons and 21.4 tons, respectively. Aluminum accounts for 23-24%, steel and iron for 20%, and the battery modules, which go through material production and refining, account for the highest proportion at 36-40% of the total carbon footprint.

Fredrika Klarén, Head of Sustainability at Polestar, stated, “Polestar has set carbon budgets for all Polestar vehicles as part of our commitment to achieving carbon neutrality. This budget has influenced every aspect of the product development of the Polestar 4, from material selection to the sources of energy used in our factories.” She added, “By publishing our Life Cycle Assessment, Polestar is demonstrating our efforts towards carbon neutrality while reducing greenhouse gases by a ton at a time.”

Polestar provides detailed information concerning the carbon footprint of all its mass-produced vehicles. Furthermore, it believes that the automotive industry must lead the transition to sustainable mobility, with transparency being a key element enabling this transition.

Since 2020, Polestar has been using its Life Cycle Assessment to consider various factors throughout a vehicle’s life cycle—from material supply to manufacturing and recycling—quantifying its impact on the climate in a way that is easy for consumers to understand. This helps consumers make quick and informed decisions when purchasing a vehicle. The figures released in this latest assessment include the material supply processes throughout the entire product production, indicating the carbon footprint from automotive production to delivery (cradle-to-gate), excluding use and disposal stages.

Lee Sang-jin daedusj@autodiary.kr