Volkswagen is set to transform its Wolfsburg plant into an e-mobility production base as part of its future electrification strategy. As a result, Volkswagen plans to invest approximately €460 million by early 2025 in its main factory located in Wolfsburg, Germany.

Thomas Schäfer, CEO of the Volkswagen brand, announced this during a business meeting held in Wolfsburg last Wednesday. The primary goal of this investment is to prepare for the production of the new ID.3 at the Wolfsburg plant, with the compact electric vehicle expected to begin full-scale production in 2023. Production will start on partial lines at the Wolfsburg plant, with the aim of producing the ID.3 throughout the entire factory by 2024 and further increasing production volumes by the end of 2025. Training for personnel involved in this production is currently being prepared.

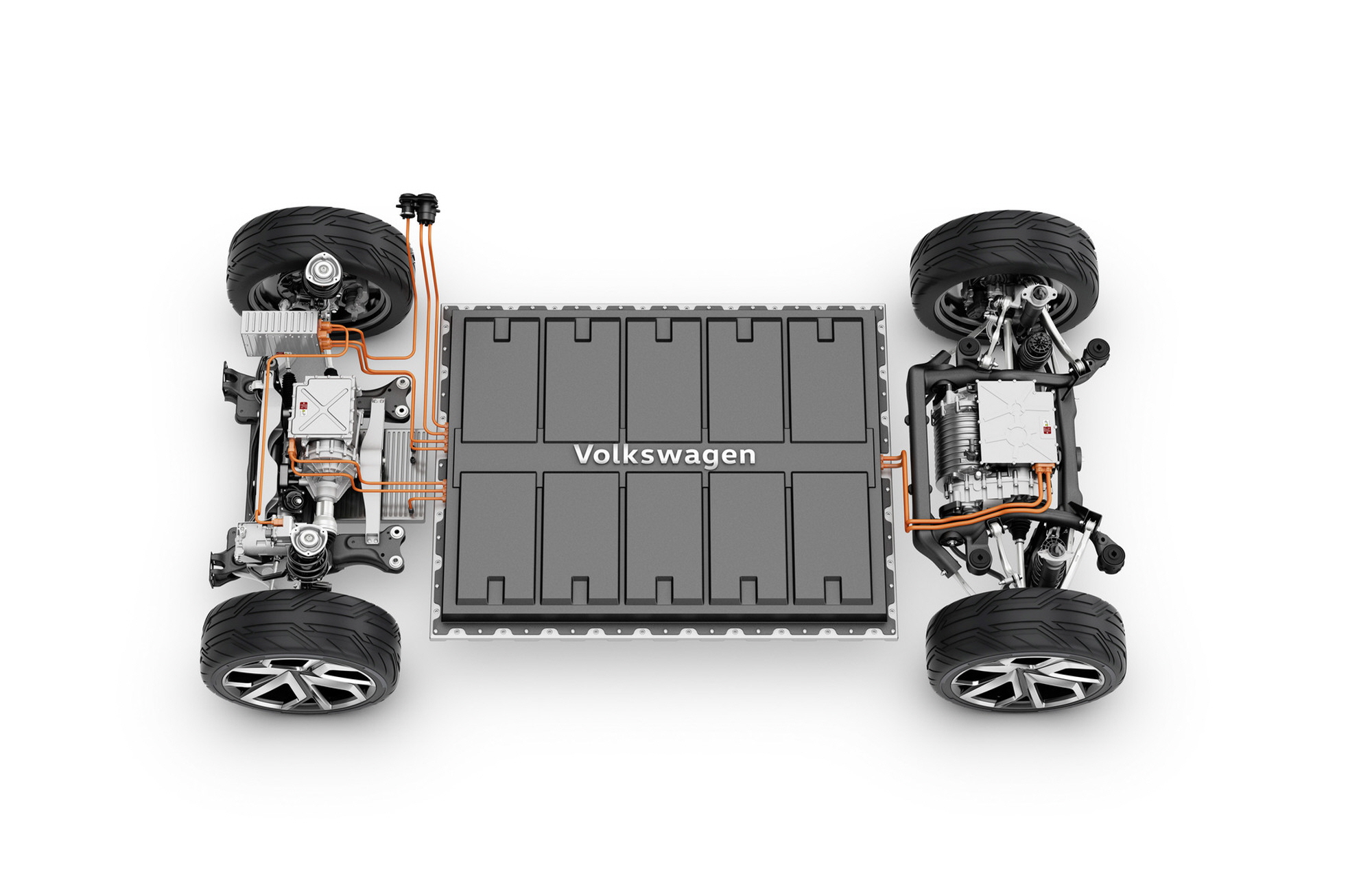

After boosting ID.3 production, Volkswagen aims to introduce additional electrified models in the globally popular SUV segment, fully utilizing the electric vehicle production capabilities in Wolfsburg in the long term. The technical foundation for these new electric vehicle models will be the Modular Electric Drive Matrix (MEB) platform, which will be further upgraded for enhanced efficiency.

This will also be applied to the ‘Trinity Project’ underway at the Wolfsburg plant.

Trinity is expected to be developed based on a system platform that can be expanded across the Volkswagen Group. Like other factories in Europe, Volkswagen plans to produce only electric vehicles at the Wolfsburg plant by the end of 2033 at the latest.

Thomas Schäfer, CEO of the Volkswagen brand and a board member of the Volkswagen Group, stated, “Volkswagen is pursuing e-mobility for everyone, and Wolfsburg will be the cornerstone of this success story. By investing approximately €460 million in this factory until early 2025, we will prepare for MEB production. Boosting ID.3 production is the first major step towards electrification at the Volkswagen Wolfsburg plant. At the same time, we are working closely with the works council to introduce additional electric vehicle models based on MEB+ to Wolfsburg, focusing on the SUV segment, which has high customer demand. Through this firm decision and investment, we plan to further enhance the plant’s competitiveness and provide our employees with a concrete and long-term vision.”

Additionally, CEO Schäfer expressed gratitude to employees for demonstrating exceptional flexibility and team spirit during what has been a very challenging economic environment this year.

Daniella Cavallo, chair of the works council at Volkswagen Group, remarked, “Wolfsburg symbolizes the future. The works council has a clear vision for the Wolfsburg plant, which encompasses cutting-edge production systems, top talent, and the most challenging pioneering spirit. Wolfsburg will continue to develop the Trinity and SSP platform projects, transitioning to an electrification production base by 2026, ensuring that it remains a strong production site for the Volkswagen brand and Group in the years to come. Furthermore, we will discuss a concrete timeline together for the stable employment of our employees. I would also like to extend my thanks to the production team at the plant for overcoming many crises throughout a difficult year.”

The first phase of the electrification of the plant will also encompass the refurbishment process for ID.3 production. Starting from 2023, in addition to being produced in Zwickau, the ID.3 will also be manufactured in Wolfsburg. The ID.3 will be the first MEB-based electric vehicle produced at Volkswagen’s largest factory, located in Wolfsburg.

Brand CEO Thomas Schäfer hinted at plans to produce additional MEB-based models at the Wolfsburg plant in the future, identifying these as electric SUV models.

CEO Schäfer stated, “SUVs represent the largest segment in terms of volume globally and are the home of our popular Tiguan model. The new model will ideally complement our bestsellers, the ID.4 and ID.5. This will allow Volkswagen to further expand its position in the market and provide customers with the high-quality vehicles they expect from us.”

Volkswagen plans to apply the MEB+, the upgraded version of the successful MEB electric vehicle platform, to its electric SUVs.

CEO Schäfer articulated, “MEB still holds significant potential, and our goal is to elevate this platform to the next level. For that, we are making substantial investments in technological advancements. MEB+ will solidify the Volkswagen brand’s position in the market going forward.” Experts, back in 2020, concluded that in-depth studies of Volkswagen’s electric platform positioned it as “the most impressive solution available from a traditional automaker in the electric vehicle market.”

Customers will benefit from various aspects of the MEB+ platform, including faster charging speeds and longer ranges. Volkswagen plans to use highly standardized integrated cells produced at its own battery cell plant in Salzgitter (set to commence production in 2025) within the system.

Volkswagen has launched a robust brand strategy in anticipation of the electrification and digital mobility era, coinciding with its “acceleration” declaration. By enhancing the “Energize” program, the brand strategy has been further bolstered. At the core of this strategy is the scalable SSP platform, based on the Trinity project, which will be implemented sequentially according to software development timelines. It remains undecided on which production line within Wolfsburg the Trinity project vehicles will be manufactured, and to this end, Volkswagen is keeping open the possibility of constructing a new plant in Bamberg.

Lee Sang-jin daedusj@autodiary.kr