Hyundai Mobis is building a new dedicated electric vehicle module factory in Ulsan. This production base will supply key modules such as chassis and driver’s seats for next-generation electric vehicle models. This proactive investment aims to secure a stable production base to enhance global competitiveness in the field of future mobility in response to the expanding global electrification market.

On the 9th, Hyundai Mobis announced that it signed a Memorandum of Understanding (MOU) with Ulsan Metropolitan City for the establishment of the electric vehicle module factory. The signing ceremony, held at Ulsan City Hall, was attended by Mayor Kim Du-gyeom and CEO Lee Kyu-seok of Hyundai Mobis.

The new electric vehicle module factory will be located near the new electric vehicle plant that Hyundai Motor is constructing in Ulsan. Hyundai Mobis plans to supply key modules such as chassis and driver’s seats for the Genesis electric vehicle models that Hyundai produces at this plant. The chassis module is a combination of an electric motor, inverter, and other components, supplied to finished vehicles. Approximately 90 billion KRW will be invested in building the module factory, which aims for completion in the second half of 2025.

*Chassis Module: A unit component that integrates the suspension, steering, and braking systems that compose the vehicle’s lower structure.

*Driver’s Seat Module: A unit component consisting of driving information, infotainment, climate control, and airbags.

This new factory construction by Hyundai Mobis is a proactive response to the expansion of the global electric vehicle market. Hyundai Mobis is continuously expanding its production bases for key electrification components both domestically and internationally to respond to automakers that are moving into the electric vehicle market.

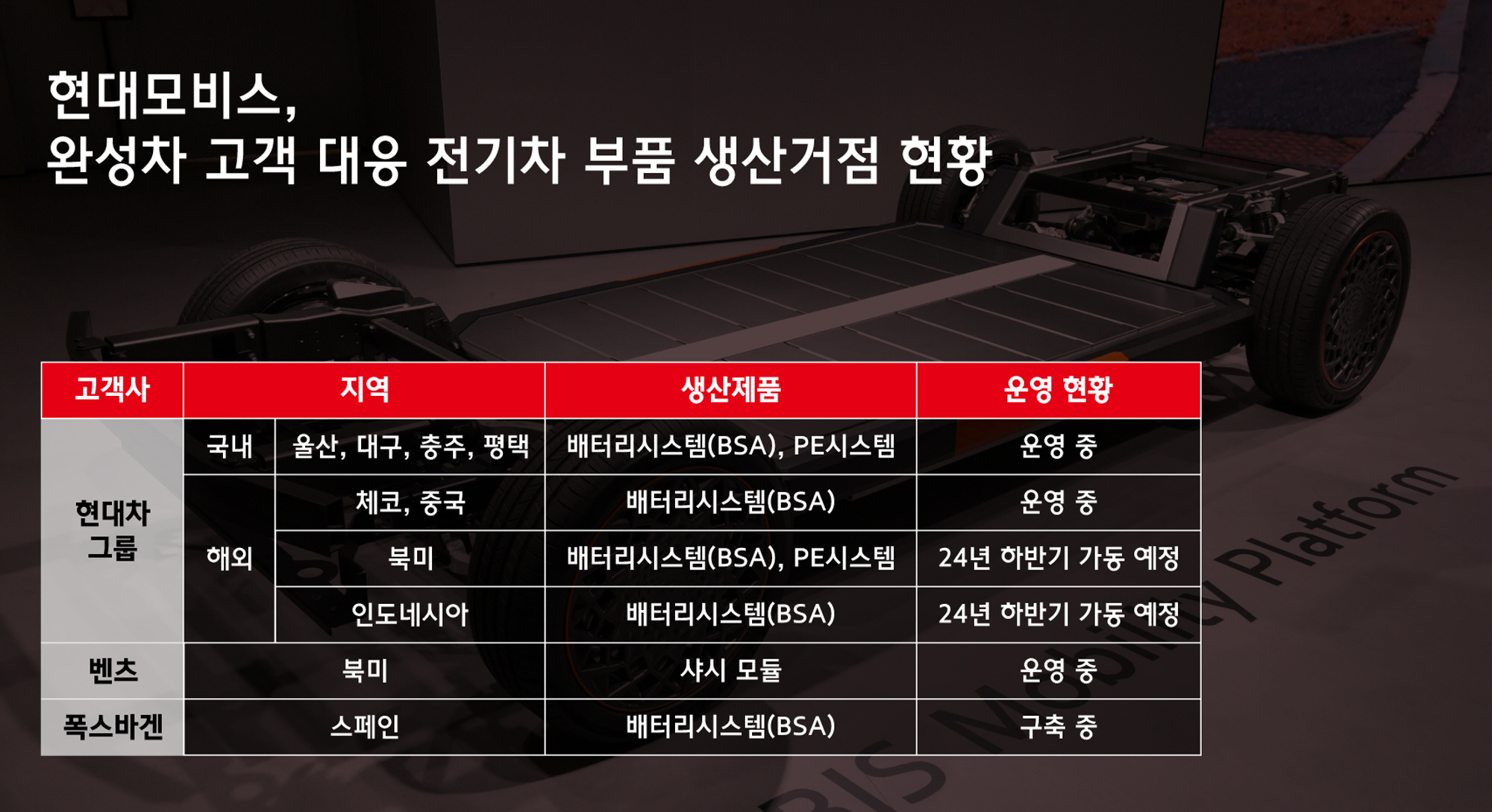

Hyundai Mobis operates battery systems (BSA) and PE systems factories that are essential parts for electric vehicles in Ulsan, Daegu, Chungju, and Pyeongtaek. By establishing key manufacturing locations covering the Yeongnam and Central regions, Hyundai Mobis is building a stable supply chain for components necessary for domestic electric vehicle production.

Hyundai Mobis is also expanding its electrification production bases in strategic overseas locations. The company produces battery systems in China and the Czech Republic and is currently building a battery system (BSA) plant in Indonesia. In particular, to respond to the Hyundai Motor Group’s new electric vehicle plant, the Metaplant America (HMGMA), in North America, Hyundai Mobis is constructing local production bases for battery systems and PE systems.

Additionally, Hyundai Mobis is establishing a production base in Alabama, USA, supplying modules for electric vehicles to Mercedes-Benz, and recently began constructing a dedicated factory in Spain to supply battery systems (BSA) for Volkswagen electric vehicles. In this way, Hyundai Mobis is pursuing a strategy of continuously increasing overseas orders from global automakers by expanding local production bases for key electrification components.

Lee Hyun-woo, head of the Module BU at Hyundai Mobis, stated, “We will strengthen our partnership with finished vehicle customers by reliably supplying modules optimized for the various electric vehicle models coming out in the future.”

By Lee Sang-jin daedusj@autodiary.kr